How to Select the Right Knife System for Your Combine Harvester

A row crop farmer’s entire year culminates at harvest time – it’s when all the preparation, investment, hard work and patient waiting comes to fruition. By the time fall rolls around, you’ve already done what you can to maximize growth, control weeds or pests and manage soil moisture, leaving the rest up to Mother Nature – now the only thing you can control is the quality of the cut.

While engine power can impact how quickly and easily you can harvest your crop, but it’s the header bar – and specifically the knife assembly – that plays a critical role in how cleanly, efficiently, and reliably your machine cuts through crop.

Whether you’re harvesting soybeans, small grains, or canola, the right knifehead can help reduce losses, improve speed, and ensure consistent cutting in all conditions.

Here’s what to consider when selecting the right sickle or knifehead for your machine – and how our new product lineup can help you get the most from every acre.

Why Knife Quality Matters

The knife is the heart of the cutter bar. A worn, dull, or ill-matched knife won’t just slow down your harvest – it can increase fuel usage, lead to ragged cuts (which leave crop behind or cause spoilage issues), and even cause downtime during the busiest days of the year.

In short, a quality sickle or knife system:

- Increases cutting efficiency

- Reduces crop loss

- Improves fuel economy

- Minimizes wear on the knifehead and guards

- Keeps your harvest on schedule

Key Considerations When Choosing A Combine Knife

Choosing the right knife system isn’t just about what fits your combine, it’s about what performs best for your specific crop, farming system and even farm topography. Different knife styles and sickle section features are better adapted to different crops and farming conditions, and can have a knock-on effect on efficiency if you don’t choose the best type for your setup. Here’s a look at some of the options available.

Single vs. Sectional Assemblies

The choice between running a single-piece sickle or a sectional knife assembly almost always comes down to practicality – but performance is a key consideration, especially for high-yield applications.

Single-piece knives

Available from Wearparts up to 40ft in length, single-piece sickles arrive assembled, ready to fit on your harvester. They’re ideal for operators seeking maximum strength, consistency, and minimal in-field vibration. They reduce the chances of misalignment or weak points during harvest, but for obvious reasons are much more challenging (and therefore expensive) to transport.

Sectional bolt-together knives

Sectional knives are pre-manufactured in short sections that are then bolted together on-site. These are easier to handle, ship, and install, especially for longer headers. They also allow for faster replacement of damaged sections – for instance, it’s more common for a sickle to wear out near the head end of the knife, and with a sectional knife you can simply remove and replace this section instead of replacing the whole knife, or the individual sickles. For long headers, a sectional knife can save significantly on shipping and handling costs compared to a one-piece knife.

Traditional sickle sections

Standard replacements for existing headers are often sold as single sickle sections – triangular sections like pizza slices that are individually bolted or riveted onto a sickle bar. The sickles are placed in an alternating pattern – one face up and the next face down – all along the bar. If a sickle blunts or breaks, it can be removed and replaced for a highly-cost effective solution. However, this is a fiddly task leading to significant downtime, especially for longer headers with hundreds of sickle sections.

Knife Format Comparison

| Knife format | Pros | Cons | Best for |

| One piece knife | Stronger Less vibration Fewer wear points | Harder to ship and install Difficult to replace broken sections | High speed, high yield operations Large farms |

| Sectional knife | Easier to transport and install Simple and quick to replace sections | Potential for wear at the joins Costs more than single sickles | Medium to large farms Varied crops and ground conditions |

| Single sickles | Low cost replacement | Time consuming to replace full assembly | Small headers, older machinery, spot repairs |

What other things should I consider when choosing a knife system?

From OEM to aftermarket, there are lots of different knife systems on the market – and within those knife systems, there are even more options that allow you to tweak performance to your specific crop type, conditions, machinery and even farm topography. Here’s a look at some of the things you should consider, especially if you’re looking to move away from standard or OEM components to something more advanced.

Crop Type

Different crops have different stem densities, moisture levels, and cutting behaviors. Moving away from factory standard or OEM systems can help you to achieve more precise and efficient cutting operations. For example:

- Soybeans and canola have stems that can be tough and stringy, so may benefit from a knife equipped with sickle sections with more aggressive serrations for additional cutting power

- Small grains like barley and wheat have finer stalks that benefit from finer sickle serrations – producing a clean shear without shredding, for smoother cutting action with less risk of clogging the knife.

Harvest Conditions

In an ideal world, you’d have a dry summer and fall, your crops would be standing straight and tall and the ground underfoot would be dry. But an increasingly unpredictable climate means that many farmers will be dealing with suboptimal conditions – problems like weedy or damp fields and lodged areas where crops have toppled over and become tangled due to wind and rain.

These conditions can lead to your knife getting jammed with residue, and blunt or broken sickles. Starting out with a knife that has the power and durability to cut easily even in difficult conditions is always worth the investment – you’ll save significantly on time and replacement parts, while also reducing long-term wear on your knifehead and drive system.

Speed & Efficiency

The window for harvesting crops can often be pretty short – you’re waiting for that perfect moment when optimal crop dryness and weather conditions intersect. And if you’re farming a lot of acres, that means you have even less time to bring home the gold – which means running your combine at higher speeds.

Speed puts significant strain on the combine in general, but especially the knife – and this is where poor quality components will often let you down. We can’t stress it enough – look for quality in every aspect, from sickle sections to wear plates and rollers.

Precision-engineering, heat treatments, self-sharpening technology and enhanced strength-to-weight ratios all make your operations more effective and efficient, reducing downtime so you can get your crop in quickly when it counts. Look for systems that are quick to inspect, easy to service, and built to last, especially when the pressure is on.

Compatibility

Sticking to OEM parts for your specific combine always feels like a safe bet – you get guaranteed compatibility, and surely the big brand names are always the best quality, right? This is often true – but not always. While some OEM manufacturers specialize in harvest machinery and parts, others are generalists – and if you’re finding their parts don’t hold up in your specific conditions, it’s worth considering a change.

At Wearparts, we bring you the best of both worlds – advanced compatibility for all major machinery brands AND specialist harvesting expertise and technology from industry leaders like Group Schumacher. As with everything we supply, these parts are designed for advanced performance and durability in the field, be engineers focusing in closely on the features farmers need to achieve optimal efficiency and yields.

Product Spotlight: Group Schumacher EasyCut II

As one of the most respected names in cutting systems worldwide, Group Schumacher brings renowned German precision and innovation to the table. Their EasyCut II knife system is designed to answer many of the challenges farmers face in the midst of an unpredictable climate and a hugely competitive marketplace.

What is EasyCutII and what are the benefits?

EasyCut II is a modular, universal system that fits all crops and all headers. It’s a sectional system that adapts to any header length, but is easy to handle and ship, making it accessible to all farmers.

The system is designed for exceptional stability and cutting force, plus a significantly extended wear life in the field, which is why it aligns so closely with the Wearparts philosophy. Its sickle sections are hardened and galvanized for durability, with optimized tooth design to suit all crops and conditions.

The uniquely balanced guard system has two cutting edges, with guards bolted top and bottom for exceptional smoothness and vibration resistance – choose from standard, comfort and premium assemblies with a mix of wear plates and roller guides. EasyCut II is ideal for operations looking to combine high-performance cutting with low-maintenance simplicity. It’s especially effective in lodged crops, uneven terrain, and long hours – keeping your harvest moving efficiently.

What sets EasyCut II apart?

- Modular knife design adapts to any header size, while quick-change sections simplify service and reduce downtime. All components fit in a 9ft box for easy shipping.

- Balanced guard design with optional roller guides reduces vibration, improving operator comfort and reducing wear on the header.

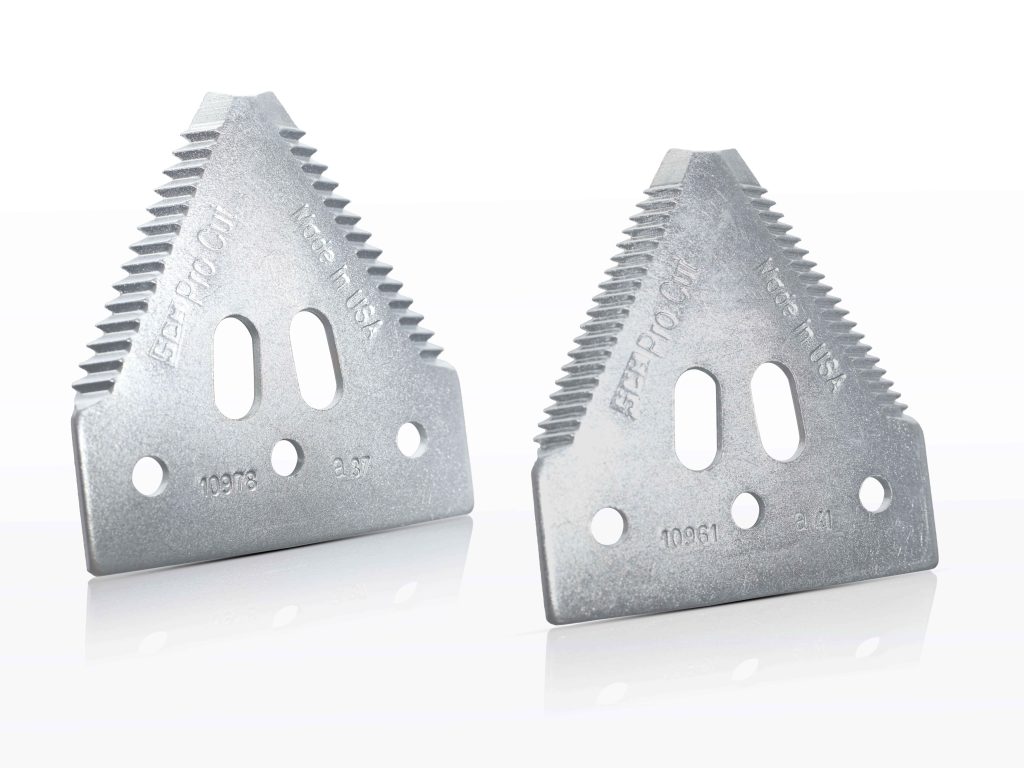

- ProCut teeth are hardened and galvanised for optimal cutting in any conditions – 7,11 and 14tpi versions available, plus lightweight ProCut Air variant

- Fully bolted design for easy replacement/adjustment

Parts that match your harvest goals

Choosing the right sickle or knife assembly isn’t just about what fits your combine -it’s about selecting parts that support your harvest goals.

We’re relatively new to harvest parts at Wearparts – but we’re old hands at understanding what farmers really need on the ground, and we’ve used that knowledge and feedback to develop a harvest range that delivers more. From durability and wear life to expert customer support when you need it most, we’ve got your back – and so does our network of trusted ag dealers.

Talk to your Wearparts dealer today or speak to our team about getting the right fit for your field.