Planting Season Prep: How to Avoid Planter Downtime This Spring

Winter weather has the US Midwest in its grip right now – but it won’t be long until the first signs of spring start appearing, so farmers are already thinking ahead to warmer days and the much-anticipated start of planting season.

While some states have the luxury of a relatively long planting window, others – including Iowa, Indiana, Missouri and Nebraska have shorter windows, sometimes as little as four weeks after the risk of frost has passed. This means that any unexpected downtime due to planter problems can seriously impact your ability to get seeds in the ground while conditions are optimal.

So how can you make sure your planter is ready to go as soon as the planting window opens – and how can you avoid unexpected equipment failures that slow you down once planting gets started? Let’s take a look at some essential planter checks and considerations every farmer needs to take into account as planting season rolls around.

Inspect your planter

First things first – after many months sitting in storage, it’s time to get your planter outside or into the workshop for a thorough once-over, starting with a visual inspection and cleaning if necessary. You should use compressed air to remove any dirt, dust or debris that has accumulated over the fall and winter so you can get a clear view of any worn parts or other problems that need attention. Routine checks should include:

- Overall structural soundness – check for cracked or bent components and signs of irregular wear

- Check all filters and replace as necessary

- Lubricate moving parts

- Top up oil, water and coolant levels

- Ensure firm connections on all vacuum, seed delivery and hydraulic lines

- Look for cracked or perished hydraulic hoses

Optimize planter performance

Once you’ve checked all the basics, it’s time for more focused inspection and calibration to ensure your planter is in tip-top condition before you head to the field. Here are some key checks to carry out:

Row Unit Spacing

Use a measuring tape to ensure all row units are properly spaced. A small offset can lead to big problems during field operations and harvest.

Seed Opener Adjustments

Ensure openers are sharp and within the diameter tolerance specified by the manufacturer, which is usually 1.75 to 2 inches. Check the pinch point using the credit card method, ensuring adequate contact between the disks for precise trench cutting – add spacers if necessary. See below for more information on our Guaranteed True™ seed openers.

Gauge Wheels

Ensure proper contact between the gauge wheels and disk openers, making sure gauge wheels can still be turned by hand with slight pressure.

Meters and Seed Plates

Inspect the vacuum seals and brushes on the meters. Check that the correct seed disks, knockouts and double eliminators are installed for the crop being planted. Inspect finger pickup meters to ensure that the fingers spin freely and that all finders open and close properly.

Seed Placement System

Clean seed tube sensors and check the condition of the seed drop tube. For high-speed equipment, check the condition of seed belts and brushes.

Row Cleaners

Spin the cleaners to check bearings and linkages for signs of wear. On pneumatic systems, check for leaks in the airbags and airlines.

Row Unit Downforce

Check for leaks in air lines or hydraulic hoses, as well as airbags and cylinders. Be sure all gauge wheel load sensors are working and reading properly.

Closing System

Inspect the bearings in the wheels. Check the alignment of the closing wheels by setting the planter down on concrete and pulling it forward 4 to 5 feet. Make sure the closing system wheels are centered over the line that is created on the concrete by the double disk openers.

Selecting Replacement Components for your Planter

The most important components on your planter are the seed opener, the gauge wheel and the gauge wheel arm – if and when these components need to be replaced, it’s vital you select high quality parts that meet or exceed the OEM specification.

Failing to do so will result at best in downtime while you replace worn parts midway through your planting cycle, and at worst, unexpected breakages in the field. Here’s a look at some of the reasons Wearparts planter components are better than the OEM, and trusted by farmers looking to minimize downtime:

Seed Openers

Our premium Forges de Niaux seed opener assemblies represent best-in-class quality and durability, offering on average 30% longer wear life in the field than the leading competitor. These blades feature:

- Unique heat-treatment process delivering 3 distinct zones of hardness

- Harder edge, more flexible center

- Longer bevel – stays sharper for longer

- Heavy-duty bearing & rivets

- Guaranteed True®

Our Guaranteed True™ promise reflects the fact that we check 100% of our seed opener assemblies before they leave our warehouse, ensuring they achieve industry-beating tolerances for wobble and lope – a minimum of .050/1.27mm axial and .060/1.52mm radial tolerance. As a result, you can be sure our openers will run true, with no time wasted pre-qualifying blades before fitting them on your planter and no hassle of returning faulty openers. We offer a wide range of options to fit all popular planter brands.

Gauge Wheels

Wearparts is proud to be a distributor of gauge wheel technology from leading French brand, Otico. The company’s famous ‘Farmflex®’ gauge wheel and tire assemblies are chosen by Wearparts and many other OEM brands because of their longevity, efficiency and soil-friendly design. A range of solid and spoked wheels are available, with semi-solid rubber tires that offer superior puncture and wear resistance while minimizing soil compaction and downtime associated with plugging.

Gauge Wheel Arm Kits

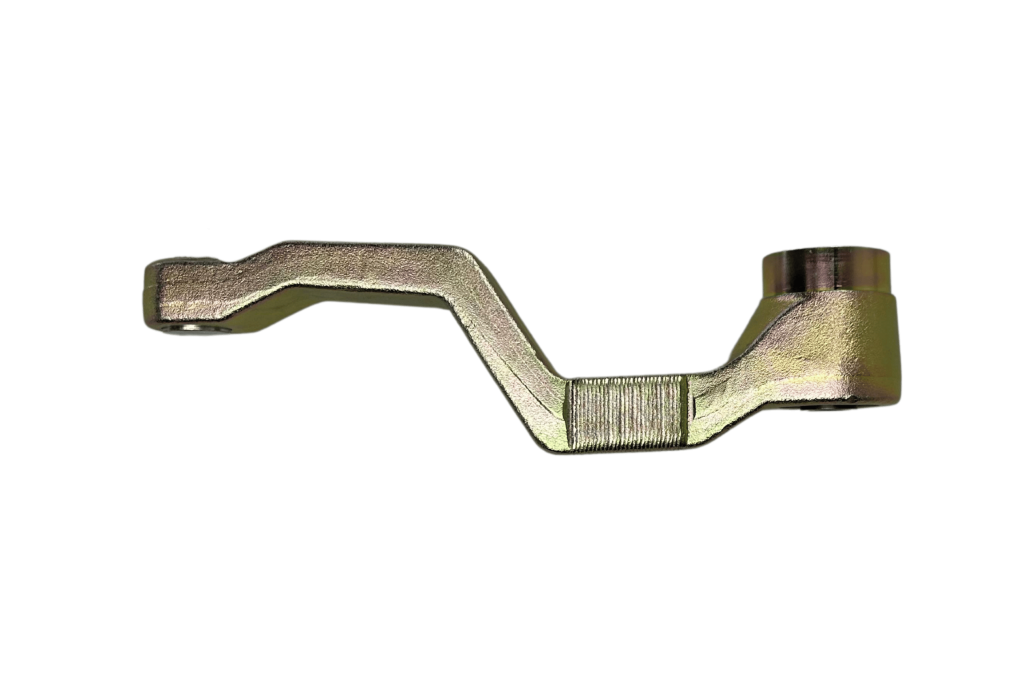

The gauge wheel arm is the part of your planter that absorbs the most force during planting applications and as such, is a common factor in planter underperformance or downtime. Our new gauge wheel arm kits have been designed based on feedback from farmers and in line with our commitment on extended wear life.

- Made from heavy duty forged 4140 steel alloy construction to eliminate flex

- Advanced fatigue resistance

- Thicker and stronger than OEM spec

- Maintenance-free sealed design – no need to grease

- Laser clad wear plate

Each kit includes a right hand or left-hand arm, right or left threaded directional studs for easy installation plus all nuts, lock washers & shims.

Need help with planter parts?

Our knowledgeable sales team is waiting to take your call – whether you need product recommendations for your own planter or you’re an ag dealer looking to solve for your customer, get in touch for tailored advice today.